The comprehensive services include the following stages:

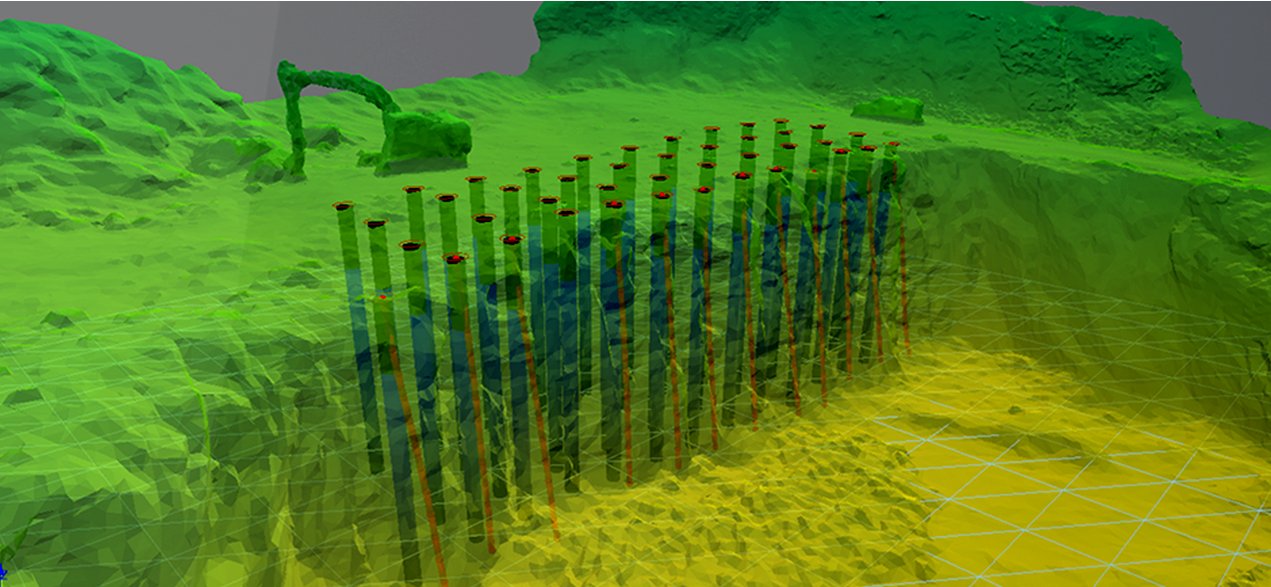

A specialized team of engineers meticulously plans the mining process. In the planning and simulation phase, AV Group considers the client’s goals and objectives, utilizing advanced software and drones to create a precise 3D digital model of the site.

Experts simulate and assess the seismic activity and the impact of air shock waves on nearby structures. An electronic blueprint for mass explosions is created, allowing for the mining processes to be executed with utmost precision and efficiency while ensuring quality and reliable results.

Drilling operations are conducted strictly according to the electronic passport to achieve optimal results. AV Group employs high-performance drilling rigs from the world’s leading manufacturers, including state-of-the-art remote-controlled models.

The drilling rigs are equipped with cutting-edge technology for high-precision positioning. Operators determine the well’s position to the centimeter and oversee the drilling process. Specialized software is used to determine the energy required for drilling and other parameters to ensure high-quality blasting operations.

AV Group offers RC drilling services for ore deposits, implementing dilution control and loss reduction systems using a specialized complex for shifting ore bodies: the AVM radio markers. This provides accurate data on mineral content, as well as helps reduce dilution and minimize losses.

During the charging and blasting process, AV Group engineers consider various factors: the mining and geological conditions, the required quality characteristics and parameters of the blasted rock mass, and the parameters and excavation schemes of the mining equipment used.

Our specialists select the best explosives formulation based on the client’s needs and work conditions and monitor the quality of the explosives produced, including their density, detonation velocity, and the relative effectiveness of the explosives.

Borehole charging is carried out by mobile mixing units (MMUs) designed by AV Group drawing on years of experience in diverse conditions. Our MMUs are equipped with modern systems for managing and controlling the quality of the explosive manufacturing process.

In conducting blasting operations, AV Group employs leading global practices, strictly adhering to safety measures and quality control. Engineers assess the fragmentation composition to ensure the quality of the blasted rock mass and enhance the efficiency of subsequent mineral extraction processes.

AV Group uses electronic initiation systems to manage the breakdown and monitor the quality of the blasted mass. Specialists monitor the environmental impact of blasting operations, minimize the seismic effect of mass explosions and the impact of shockwaves, and control the levels of atmospheric dust and harmful gases after blasting.

A system has been developed for ore deposits to determine the displacement of ore bodies, which includes AVM radio markers, devices for their activation and detection, and software for constructing a block model of the rock mass displaced by the blast. The use of this system reduces losses and dilution of minerals and minimizes classification errors.

Submit a request to learn more about the services and products offered by AV Group.

AV Group continually enhances its technologies, invests in innovation and proprietary developments, and implements the most modern solutions for global standard mining operations.

Safety is a top priority for AV Group engineers. The company’s services adhere to the highest standards of quality, reliability, and efficiency.